Standing there, facing a shelf packed with pipes and bits, eyes locked on heaps of shiny brass parts – can you really tell which bit will stop water gushing at 2 a.m.? These brass squeeze joints? They’ve kept sinks and lines tight for years, no joke. But even now, folks who fix stuff daily – or just love weekend tinkering – still get stuck picking the correct piece for the job. A trusted brass products manufacturer is often the first place many look to avoid the guesswork.

This easy-to-follow guide covers all the basics on brass compression fittings – how they’re built, what to look for when picking one that fits your needs. If you’ve been doing plumbing for years or are just starting out at home, you’ll see why folks still trust these parts more than others around.

What Are Brass Compression Fittings?

Brass squeeze joints link tubes or pipes together – no melting metal, burning flames, or fancy gear needed. They work by pressing parts tight to stop leaks, which is why folks use ’em everywhere from homes to big buildings. Getting parts from a reliable brass products manufacturer helps ensure those leak-free connections stay solid.

The trick’s in how they’re built with three bits: a compression nut, a ring, also the main fitting piece. Twist the nut tight – it jams the ring onto the pipe, shoving it into the body so nothing leaks out. Easy to get? Sure. Still, what stuff it’s made from and how carefully it’s put together decides if it holds up for a few years or way longer.

Why Choose Brass Over Other Materials?

Brass ends up being the top pick for compression fittings – and here’s why. The mix of copper and zinc fights off rust like few others, which matters big time when waters involved. Where plastic might split from heat swings or stress, this metal holds strong no matter how hot or cold things get.

The material naturally fights germs, which helps keep drinking water safer. On top of that, brass parts stand up better to pressure compared to plastic ones – usually handling 150 to 200 PSI in regular home setups. If you go with a trusted brass products manufacturer, you’re more likely to get solid alloys built to match official requirements.

Types of Brass Compression Fittings

Standard Compression Fittings

Standard brass squeeze fittings are what you’ll usually see around. These ones use an old-school setup that’s got a brass ring and sleeve combo. For copper, brass, aluminium – or even certain plastics – they do the job just fine. You can get them in widths from 1/8 inch up to 2 inches across.

Folks who work on pipes usually go for basic squeeze-type connectors when dealing with water flow systems, fuel lines, or cooling setups. What’s cool about these bits is you can take ‘em apart and put ‘em back together again and again – just swap out the ring thingy, and the tight fit stays solid.

Flare Compression Fittings

Flare fittings work another way when it comes to tight links. Rather than squeezing a sleeve, they attach to tubes widened into a 45° bell shape. That spread-out tip fits snugly onto a sloped surface within the connector’s core, forming a super solid bond.

What’s the deal with flare fittings? These work great where shaking happens a lot or when you need to hook up and unhook often. You’ll spot them in car gas lines, AC units, even heavy-duty fluid setups at factories.

BSP Compression Fittings

British Standard Pipe bits are common where UK-style plumbing’s used. They’ve got straight or angled threading, show up as straights, bends, Ts, even downsizes. A solid brass products manufacturer will usually stock both these and NPT kinds for customers worldwide.

Key Applications Where Brass Compression Fittings Excel

Residential Plumbing Systems

In your house, brass compression joints keep things running without much notice. These bits link water pipes to taps, loos, washers, or even dish cleaners. Peek under your kitchen tap – there’s probably a brass joint tying the stop valve to the feed line.

These parts work great in homes since you won’t need torches or special skills to set them up. With just everyday tools, anyone can swap out a water line on their own – no pro needed. Still, learning how tight is right keeps things from dripping or getting crushed by too much force.

Commercial and Industrial Systems

Factories often count on brass compression fittings when setting up air-driven tools, fluid transfer setups, or production-line tubing. These spots install them for moving pressurized air, handling cooling fluids, or linking measurement gear. Since they let workers make solid joins fast, repairs or upgrades take less time to finish.

HVAC and Refrigeration

Cooling and fridge setups use brass squeeze joints for coolant tubes. Since escaping gas can mess up performance or pollute, these need to stay totally sealed. Usually, flared brass connectors handle the job – built tough enough to lock in pressurized fluids without failing.

How to Select the Right Brass Compression Fittings

Understanding Size and Thread Standards

Fitting the right size might sound easy, but it trips up plenty of folks. These compression joints go by the outer width of the pipe – what matters is how wide it is from side to side, not what’s inside. Use a measuring tool that pinches tight on the edges; don’t guess – many tubes called half-inch really stretch out to five-eighths across.

Thread types bring extra confusion. NPT ones narrow toward the end, using the thread shape to seal; on the flip side, BSP can stay straight or slope inward. Using mismatched kinds almost always leads to drips or damaged threading. Look at what you’ve got already or review blueprints prior to buying.

Assessing Pressure and Temperature Requirements

Each brass compression joint comes with set pressure and heat boundaries. Regular home-use joints usually manage 150 PSI when it’s cool, though their strength drops once things get hotter. For heavy-duty jobs – say, in hydraulics – you’ll need parts built to endure 3000 PSI or higher.

Frigid or scorching temps can mess with how things work. Though brass holds up fine through wild temp swings, the sleeve and seals might struggle. When heat climbs past 250°F, you’ll likely require upgraded sleeves built for that kind of heat. Get in touch with your brass gear maker to check what official ratings apply to your setup.

Quality Indicators to Look For

Heavy ones usually mean better material inside – lightweight versions often hide weak metals under a shiny cover. Check how smooth the screw parts look; rough edges suggest low-quality workmanship.

Famous labels often share material evidence, stress data, yet also their operating standards. See whether these lines up with references like ASTM B16.22, ASTM B16.26, or major ISO benchmarks. Documents such as certificates aren’t fluff – instead, they reflect actual tests and reliability you can verify.

Installation Best Practices

Preparation Steps

Success starts long before you grab a tool. Use the proper tube cutter to make clean cuts – never a hacksaw, because it creates jagged ends. Smooth out burrs on both inside and outside edges so ferrules stay intact while seals do their job. Small bumps may look okay, yet they can tear into connections or lead to leaks under pressure.

Clean the end of the tube properly – wipe off oil, dirt, or any corrosion. Even though squeeze-type joints cope with imperfections more easily than liquid kinds, a neat connection holds up better in the long run.

Proper Assembly Technique

Start by putting the compression nut on the tube. Next, slide on the ferrule so its narrow side points toward the nut. Push the tube all the way into the fitting until it can’t go further – stopping short leads to drips. Twist the nut snug by hand. After that, grab a couple wrenches to finish turning it tight.

Too much force smashes the sleeve, messes up screw parts; too little lets water slip through. Most cases need just a turn or maybe a bit more after finger tightening. Notice when it gets harder to twist – then quit.

Testing Your Installation

Don’t take it for granted that a compression joint won’t leak – always check. When dealing with water pipes, turn on the valve bit by bit while keeping an eye out for seepage. Fill the whole system with pressure then leave it alone awhile, scanning every part up close. Small leaks usually show up as damp spots instead of steady drops.

If there’s a drip, hold off on cranking it down tighter. Check the setup first – did the tube go all the way in? Is the sleeve sitting right? Occasionally, backing it off and rebuilding with a fresh sleeve fixes ongoing drip.

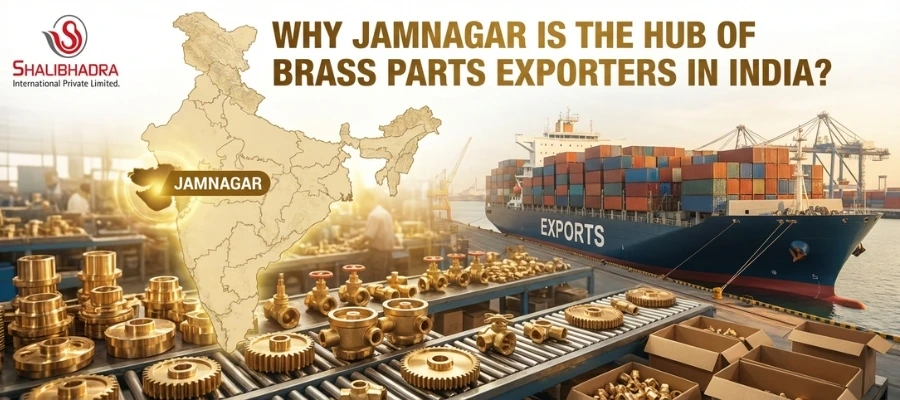

Choosing the Right Brass Products Manufacturer

Teaming up with a well-known brass maker means you’ll get solid materials, help when needed, maybe even faster deliveries. Check if they’ve got clear quality controls, labs for checking output, plus on-hand engineers. Firms around since way back tend to know their stuff – designs work better, production runs smoother.

Check samples first – don’t order big batches right away. Looking at the real item shows build details pics or specs miss. Try them out in your setup if you can, so you know how they work before buying a lot.

Conclusion

Brass squeeze joints are old-school gear still keeping up with today’s needs. Whether it’s fixing a leaky pipe or hooking up complex machinery, they work well over time if you pick the right one and set it up correctly.

Figuring out the kinds, where they’re used, and how to pick them helps you choose smart – stopping issues early. No matter if you’re hooking up one sink pipe or setting up an entire network for liquids, the rules stay the same: go with what fits your needs, set it up right, and get reliable parts from known suppliers.