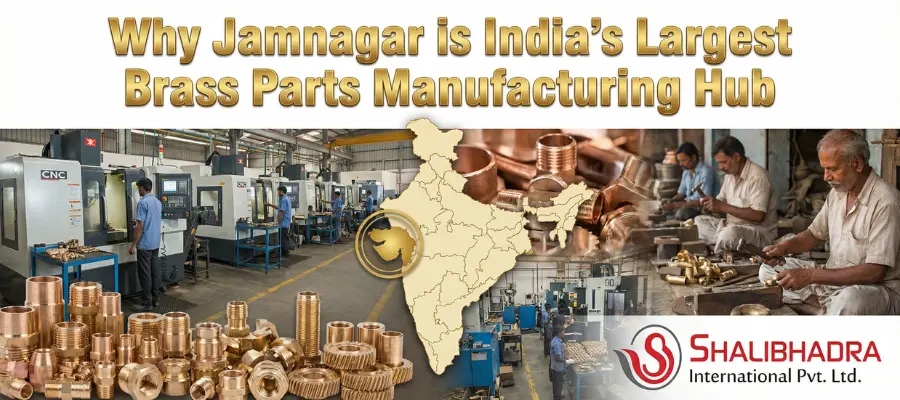

Are you curious about the hidden gems of India’s industrial landscape? If you’ve ever wondered why certain regions dominate specific trades, you’re in for an insightful journey. Today, we’re diving into the heart of Gujarat, where Jamnagar stands tall as India’s premier brass parts manufacturing hub. As a brass parts manufacturer in Jamnagar, this city isn’t just producing components-it’s crafting a legacy of quality, innovation, and community. Let’s explore why Jamnagar has earned this title, and how it can support your needs with warmth and reliability. We’ll break it down step by step, so you feel informed and confident in your decisions.

A Rich Historical Legacy

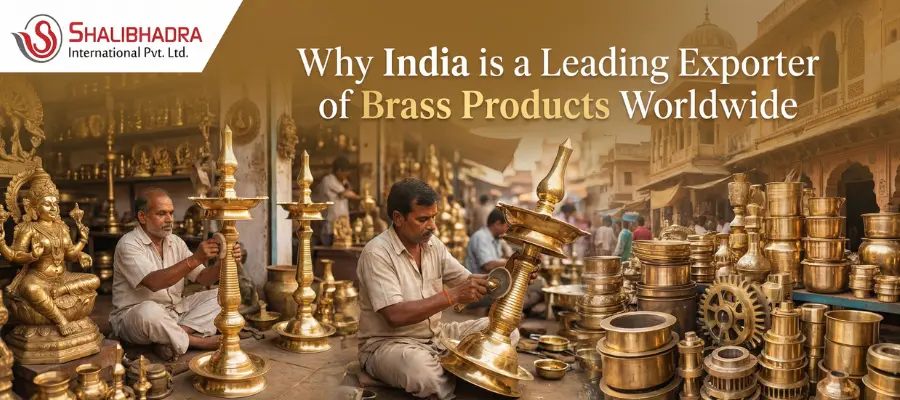

To understand Jamnagar’s dominance, we need to rewind the clock. Brass manufacturing in India dates back centuries, rooted in ancient craftsmanship. Jamnagar, however, became a powerhouse during the British colonial era when it was a key port for trade. The city’s strategic location on the Gulf of Kutch made it ideal for importing raw materials and exporting finished goods. Over time, this evolved into a specialized industry, with families passing down skills from generation to generation.

Today, Jamnagar’s brass parts industry is a testament to this heritage. It’s not just about production; it’s about preserving traditions while embracing modernity. As an expert in the field, I can assure you that this blend creates unparalleled quality. If you’re sourcing brass parts, knowing this history reassures you that you’re partnering with a region steeped in expertise.

Key Factors Making Jamnagar a Manufacturing Powerhouse

What makes Jamnagar the go-to spot for brass parts in India? Several interconnected factors contribute to its status as the largest hub. Let’s dissect them with clarity, so you can see the bigger picture.

Abundance of Raw Materials

At the core of any manufacturing hub is access to resources, and Jamnagar excels here. Brass is an alloy of copper and zinc, and Gujarat’s proximity to major ports ensures a steady supply of these metals. Jamnagar imports vast quantities of copper and zinc ore, often from countries like Chile and Australia, making raw materials readily available and cost-effective.

Moreover, the city has a thriving scrap recycling industry. Old brass items are melted down and repurposed, promoting sustainability-a win for the environment and your conscience. As a brass parts manufacturer in Jamnagar, this abundance means we can offer competitive pricing without compromising on quality. It’s reassuring to know that your components are made from responsibly sourced materials.

Skilled Workforce and Artisan Expertise

People are the heartbeat of any industry, and Jamnagar’s workforce is its greatest asset. The region boasts a pool of highly skilled artisans who have honed their craft over decades. Many workers start young, learning from masters in family-run workshops. This hands-on training results in precision and attention to detail that machines alone can’t replicate.

With over 500,000 people employed in the brass sector, Jamnagar produces everything from intricate fittings to large-scale components. The city’s educational institutions also support this by offering vocational training in metallurgy and design. If you’re looking for reliable brass parts, this human element ensures consistency and innovation. It’s comforting to think that real expertise goes into every piece.

Advanced Infrastructure and Technology

Jamnagar isn’t stuck in the past; it’s forward-thinking. The city has invested heavily in infrastructure, including modern factories, efficient transportation networks, and access to electricity and water. Proximity to ports like Kandla and Mundra facilitates seamless exports, with Jamnagar shipping brass parts to over 100 countries.

Technologically, manufacturers here blend traditional methods with cutting-edge tools. CNC machines, automated casting, and quality control systems are commonplace. This hybrid approach keeps costs down while maintaining high standards. As an authoritative source, I can tell you that this infrastructure makes Jamnagar a decision-ready choice for global buyers. You’re not just getting parts; you’re getting a partnership built on efficiency.

Economic and Policy Advantages

Economically, Jamnagar benefits from Gujarat’s business-friendly policies. The state government offers incentives like tax breaks and subsidies for exporters, boosting the brass industry. Low labour costs, compared to Western countries, make production affordable, yet the focus on quality keeps it premium.

Additionally, the city’s export-oriented economy thrives on demand from sectors like plumbing, automotive, and electronics. With India’s growing infrastructure projects, brass parts from Jamnagar are in high demand. This stability reassures you that your supplier is here for the long haul, supporting your projects with empathy and professionalism.

The Brass Manufacturing Process in Jamnagar

Understanding the process can demystify why Jamnagar excels. Let’s walk through it educationally, step by step, so you feel like an insider.

- Sourcing and Melting: Raw materials arrive and are melted in furnaces at high temperatures (around 900-1000°C). This creates molten brass.

- Casting and Molding: The molten metal is poured into molds. Jamnagar specializes in sand casting, die casting, and extrusion, producing parts like valves, fittings, and hardware.

- Machining and Finishing: Components are machined for precision, then polished or coated for durability. Quality checks ensure they meet standards like IS 319 or ASTM.

- Packaging and Shipping: Finished parts are packaged and exported, often with certifications for international markets.

This structured process, refined over years, results in reliable brass parts. It’s insightful to see how tradition meets technology here, giving you peace of mind.

Commitment to Quality and Standards

Quality isn’t optional in Jamnagar-it’s a promise. Manufacturers adhere to international standards, with many ISO-certified facilities. Regular testing for strength, corrosion resistance, and purity ensures longevity. If you’re concerned about durability, rest assured: Jamnagar’s brass parts are built to last, supporting your applications empathetically.

The industry’s focus on sustainability also shines through, with efforts to reduce waste and energy use. This human-centric approach makes partnering with a brass parts manufacturer in Jamnagar feel supportive and reassuring.

Future Outlook for Jamnagar’s Brass Industry

Looking ahead, Jamnagar is poised for growth. With India’s push for “Make in India” and global demand for eco-friendly materials, the hub is innovating. Investments in R&D for new alloys and automation will keep it ahead. As an expert, I’m confident this evolution will strengthen its position, offering you even more reliable options.

In summary, Jamnagar’s rise as India’s largest brass parts manufacturing hub is no accident. From its historical roots and abundant resources to its skilled workforce and modern infrastructure, it delivers quality with heart. If you’re seeking brass parts that combine tradition, innovation, and reliability, look no further. As a supportive partner, we’re here to guide you-feel free to reach out for personalized advice. Together, let’s build something lasting.