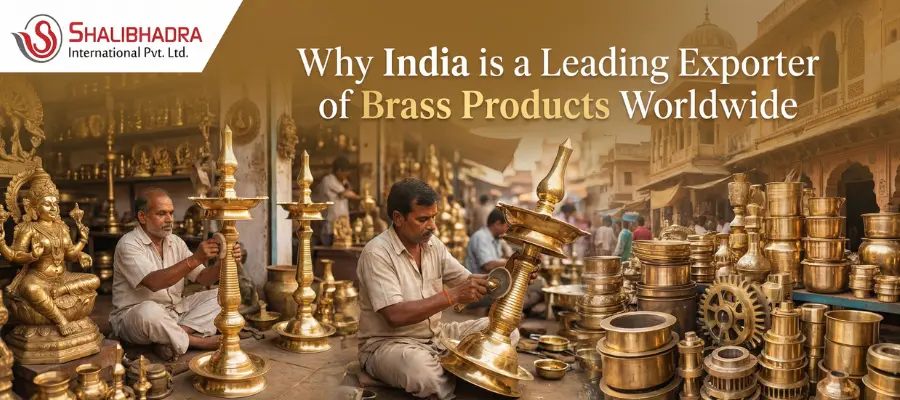

India has steadily built a global reputation for high-quality metal manufacturing, and brass components are one of the country’s strongest export sectors. Today, global industries rely on Indian manufacturers for precision, affordability, and consistent supply.

If you are sourcing industrial components internationally, working with a Brass product exporter factory india can provide both technical reliability and long-term business value. In this article, we’ll explore why India -especially Jamnagar -has become a trusted global hub for brass product exports.

India’s Strong Foundation in Brass Manufacturing

India’s leadership in brass exports did not happen overnight. Decades of manufacturing expertise, skilled labor, and strong supply chains have helped the country become one of the most dependable sources of brass components worldwide.

Indian manufacturers produce a wide range of brass products, including:

- Brass inserts

- Brass electrical components

- Precision turned parts

- Fasteners and fittings

- Custom brass components

Because of this diversity, a Brass product exporter factory india can serve multiple industries from a single manufacturing ecosystem.

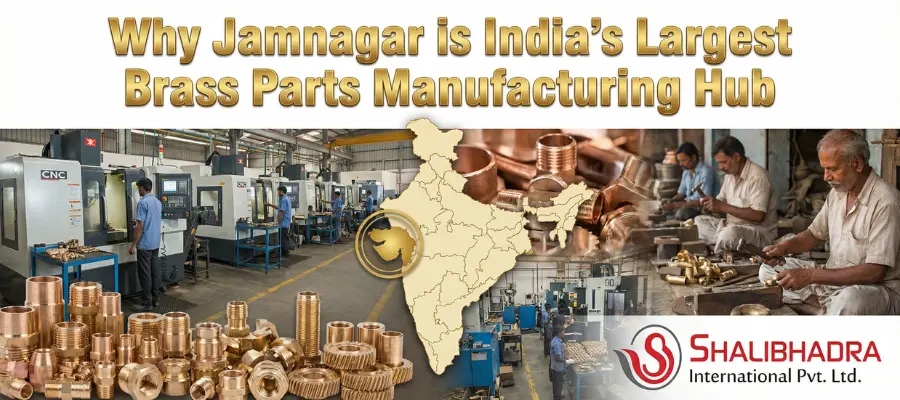

Jamnagar -The Brass City of the World

The Manufacturing Hub of Brass Products

Jamnagar, located in Gujarat, is widely known as the brass manufacturing capital of India. Thousands of small, medium, and large factories operate here, creating a powerful industrial network.

This ecosystem allows exporters to offer:

- Faster production cycles

- Competitive pricing

- Consistent raw material availability

- Skilled technical workforce

For global buyers, this means reliability and scalability when working with a Brass product exporter factory india.

Specialized Industrial Infrastructure

Jamnagar’s brass industry benefits from:

- Advanced CNC machining facilities

- Precision tooling expertise

- Export-oriented manufacturing units

- Established logistics and shipping networks

These factors make India a dependable partner for international supply chains.

Cost Efficiency Without Compromising Quality

One of the biggest reasons India leads in brass exports is the ability to balance cost and quality.

Manufacturers in India optimize production through:

- Efficient machining processes

- Local raw material sourcing

- Skilled labor specialization

- Modern quality control systems

This allows a Brass product exporter factory india to deliver precision components at globally competitive prices while maintaining strict quality standards.

For buyers, this translates into better margins, reliable performance, and long-term sourcing stability.

Skilled Workforce and Engineering Expertise

Behind every precision brass component is a skilled machinist or engineer. India’s manufacturing sector benefits from a large pool of experienced professionals who understand both traditional machining and modern CNC technology.

Indian brass manufacturers excel in:

- Custom component development

- Precision threading and turning

- Injection moulding inserts production

- Electrical brass component manufacturing

This technical expertise helps a Brass product exporter factory india meet complex international specifications with confidence.

Strong Export Capabilities and Global Reach

India exports brass products to markets across:

- United States

- Europe

- Middle East

- Southeast Asia

- Africa

Export-focused factories understand international business requirements such as:

- Consistent packaging standards

- Timely delivery schedules

- Documentation compliance

- Quality certifications

Because of this experience, global buyers often prefer working with a Brass product exporter factory india for long-term partnerships.

Quality Standards Followed by Indian Brass Exporters

Modern brass exporters in India follow strict manufacturing and inspection processes to ensure product reliability.

Common quality practices include:

- Raw material testing

- Thread gauge inspection

- Dimensional accuracy checks

- Surface finishing inspection

- Batch traceability systems

These practices ensure that products meet industrial expectations across electrical, automotive, engineering, and construction sectors.

A reliable Brass product exporter factory india focuses not only on production volume but also on precision and durability.

Custom Manufacturing Capabilities

Another reason India stands out globally is custom brass product manufacturing.

Export factories frequently work with:

- OEM manufacturers

- Engineering companies

- Electrical equipment manufacturers

- Automotive suppliers

Custom production services typically include:

- Design-based manufacturing

- CNC machining

- Thread customization

- Surface finishing options

- Bulk production support

This flexibility makes a Brass product exporter factory india a strategic partner rather than just a supplier.

Reliable Supply Chain and Scalability

Global industries depend on consistent component supply. Indian brass exporters have developed strong systems to ensure uninterrupted production and delivery.

These include:

- Reliable vendor networks

- In-house machining facilities

- Bulk production capability

- Export logistics experience

This infrastructure ensures that a Brass product exporter factory india can scale production as demand grows.

For international buyers, supply reliability is just as important as product quality -and India delivers both.

Sustainability and Modern Manufacturing

Many Indian manufacturers are now adopting sustainable production practices such as:

- Material recycling

- Energy-efficient machinery

- Process optimization

- Waste reduction systems

These improvements help a Brass product exporter factory india align with global environmental expectations while maintaining manufacturing efficiency.

Why Global Buyers Trust Indian Brass Exporters

Over time, India has built a reputation based on three core strengths:

Consistency – Reliable manufacturing processes

Precision – High-quality machining and finishing

Value – Competitive global pricing

These qualities make Indian exporters dependable partners for industries that require precision brass components.

Working with a Brass product exporter factory india often leads to long-term sourcing relationships built on trust, performance, and reliability.

India’s leadership in brass product exports comes from a powerful combination of manufacturing tradition, skilled workforce, advanced machining, and export experience. Cities like Jamnagar continue to drive innovation and production efficiency in the brass industry.

For global businesses seeking dependable component suppliers, choosing a Brass product exporter factory india offers the confidence of quality manufacturing, cost efficiency, and scalable production.

As global demand for precision components continues to grow, India remains one of the most trusted destinations for brass product exports worldwide.